Sep. 25, 2025

By Chris Gaffney, Managing Director, Georgia Tech Supply Chain and Logistics Institute | Supply Chain Advisor | Former Executive at Frito-Lay, AJC International, and Coca-Cola

Introduction

This year has felt like a lifetime in the Generative AI (GenAI) world. Tools, capabilities, and best practices are shifting monthly, sometimes weekly. For supply chain professionals, the message is clear: ongoing development is not optional. Like lean, analytics, or S&OP in prior decades, GenAI proficiency is quickly becoming a differentiator. The question is not if you’ll integrate GenAI into your workflow, but how quickly and effectively.

The Evolution of GenAI in 2025

When we look back to January, it’s striking how much progress has been made in less than a year. Early in 2025, the conversation centered on agentic AI and larger models. GPT-5 and Claude 4 improved reasoning and context windows, while OpenAI introduced ChatGPT Agent in preview, able to carry out bounded multi-step tasks like retrieving files, browsing the web, and drafting structured outputs. In supply chain, this translated into early experiments with automating shipment steps or running contract reviews in a single query — tasks that were pilot-level at best in January.

By mid-year, multimodal capabilities and enterprise copilots began shifting from concept to daily use. Users could combine text, image, and voice inputs to detect defects or summarize complex documents, and copilots became embedded inside SAP, Oracle, Microsoft, and Google platforms. For the first time, GenAI wasn’t just a tool "off to the side" but something integrated directly into the systems supply chain professionals rely on.

In the second half of the year, new capabilities started layering on: memory, specialized small models, and synthetic data with digital twins. Memory allowed copilots to recall context from prior chats or S&OP cycles, reducing rework. Domain-tuned models made GenAI lighter, cheaper, and faster for logistics, procurement, and planning tasks. And digital twin integration allowed organizations to stress-test networks under disruption scenarios, from weather to labor shortages.

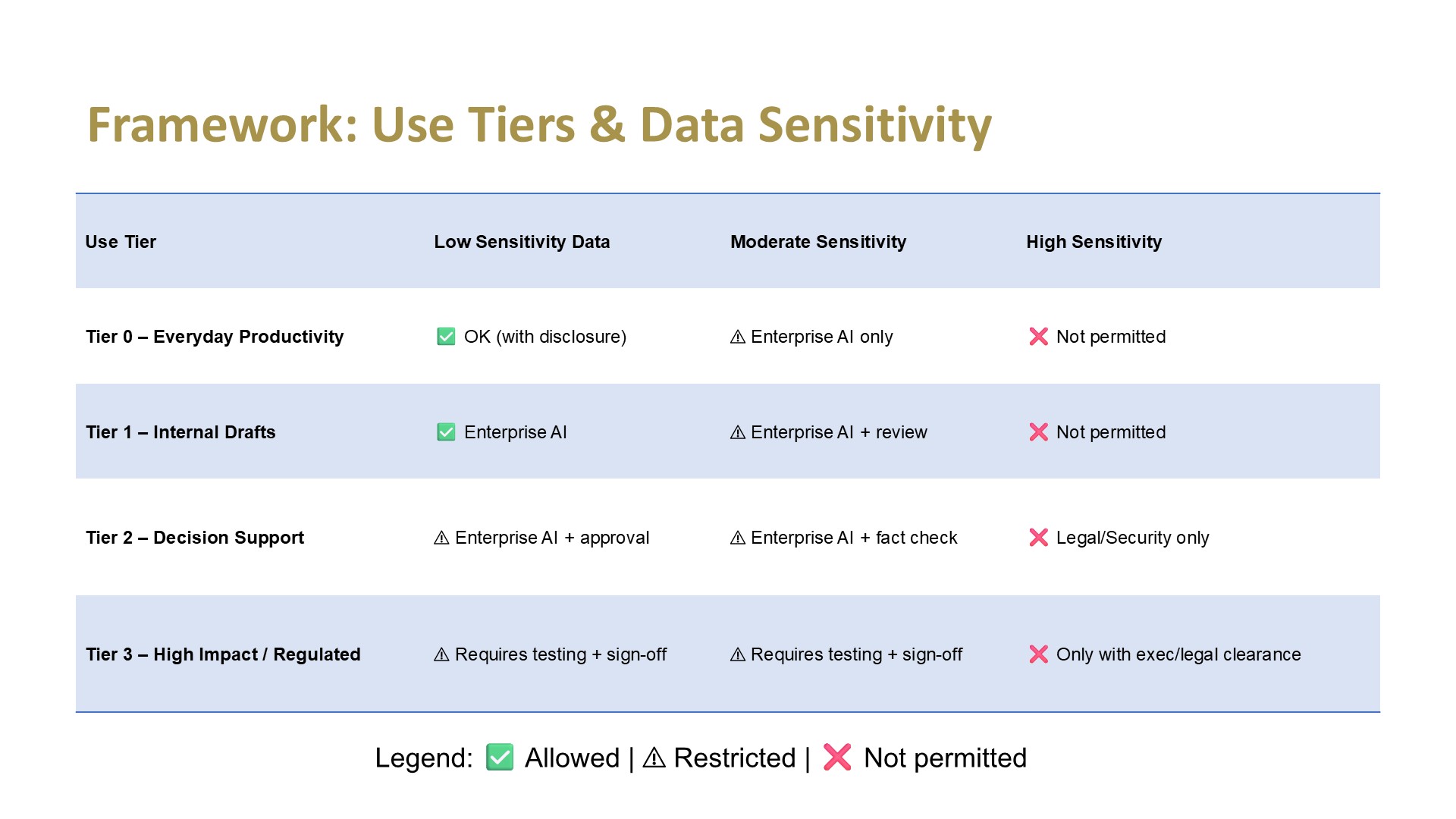

Enterprises also moved closer to operations with AI at the edge, using IoT data for predictive maintenance or real-time routing. At the same time, guardrails and compliance became a central topic, with more organizations creating clear "green/yellow/red" tiers for safe use. And in Q4, collaboration AI and hybrid architectures came to the forefront — copilots that can negotiate contracts in multiple languages, and architectures that blend closed and open-source models to balance sovereignty, cost, and security.

For mainstream individual users, the picture is simpler but still powerful. Anyone with ChatGPT Plus or Copilot today can take advantage of:

- Memory and custom instructions to save preferences and formats across sessions.

- Project-only memory (rolling out) to organize work by context.

- Agent previews like Operator to see how automation might work on bounded tasks.

- Connectors and file uploads to bring internal data into conversations.

For leaders, the focus is on policy, safe pilots, and scaling. They are:

- Sponsoring agent experiments in low-risk domains (like supplier alerts).

- Embedding copilots in enterprise systems for daily planning and reporting.

- Formalizing AI use policies so employees know what’s encouraged, conditional, and off-limits.

The net result: what started in January as experimentation has, by October, become a layered landscape. Individual users now have practical tools to reclaim time, while leaders are piloting more ambitious integrations and building the governance to make adoption sustainable.

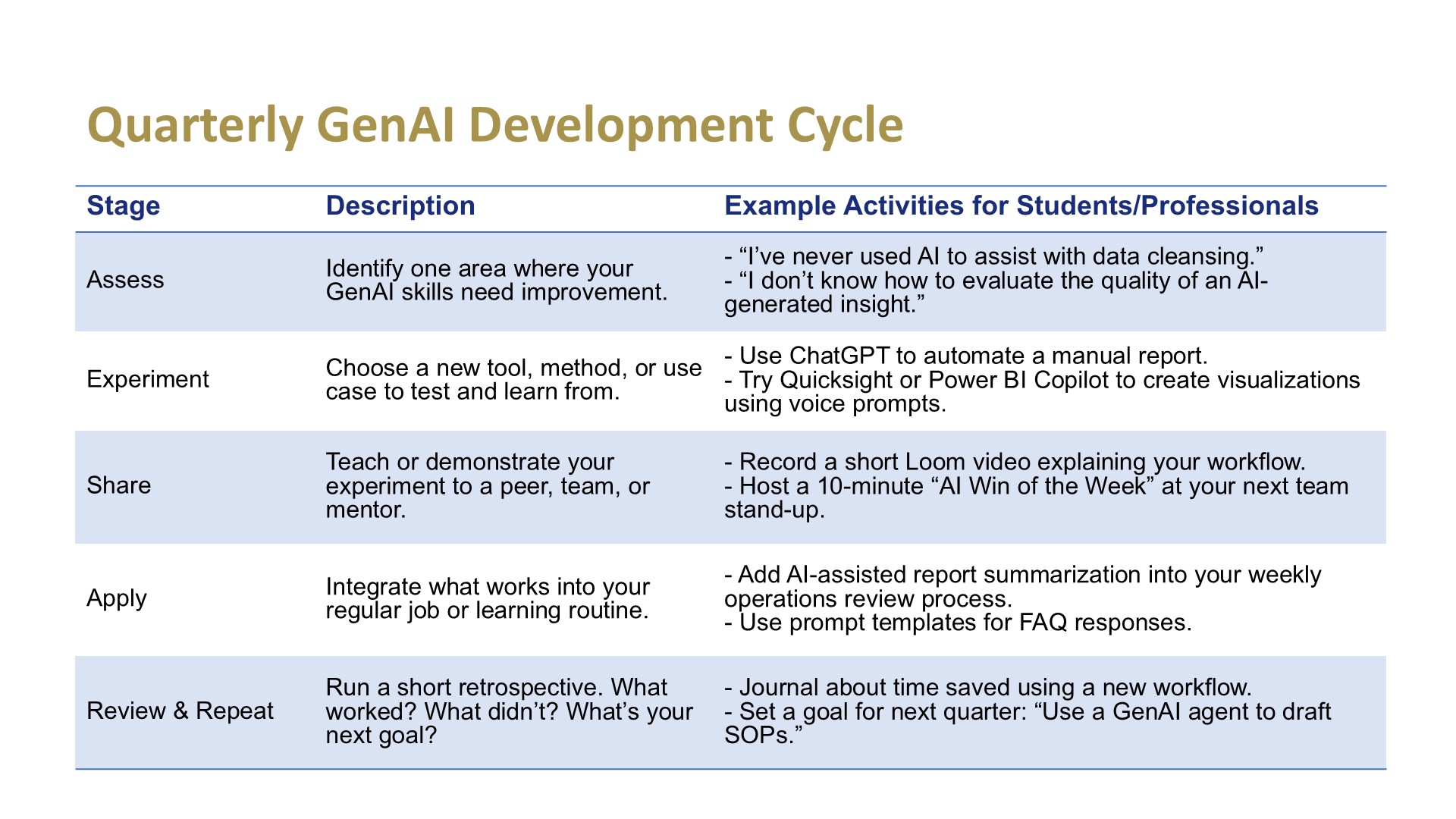

1. Action Planning is Critical

The pace of change makes a one-and-done training activity insufficient. Think of GenAI skills like fitness: it requires steady reps over time. Professionals who set quarterly development goals — experimenting with new tools, building prompt libraries, testing workflows — will not only stay current but pull ahead.

💡 Try This Quarter:

- Build a custom prompt library for routine tasks (e.g., supplier follow-ups, KPI summaries).

- Test one open-source tool such as LangChain or Haystack.

- Use AI to summarize two recent meetings and validate output with your notes.

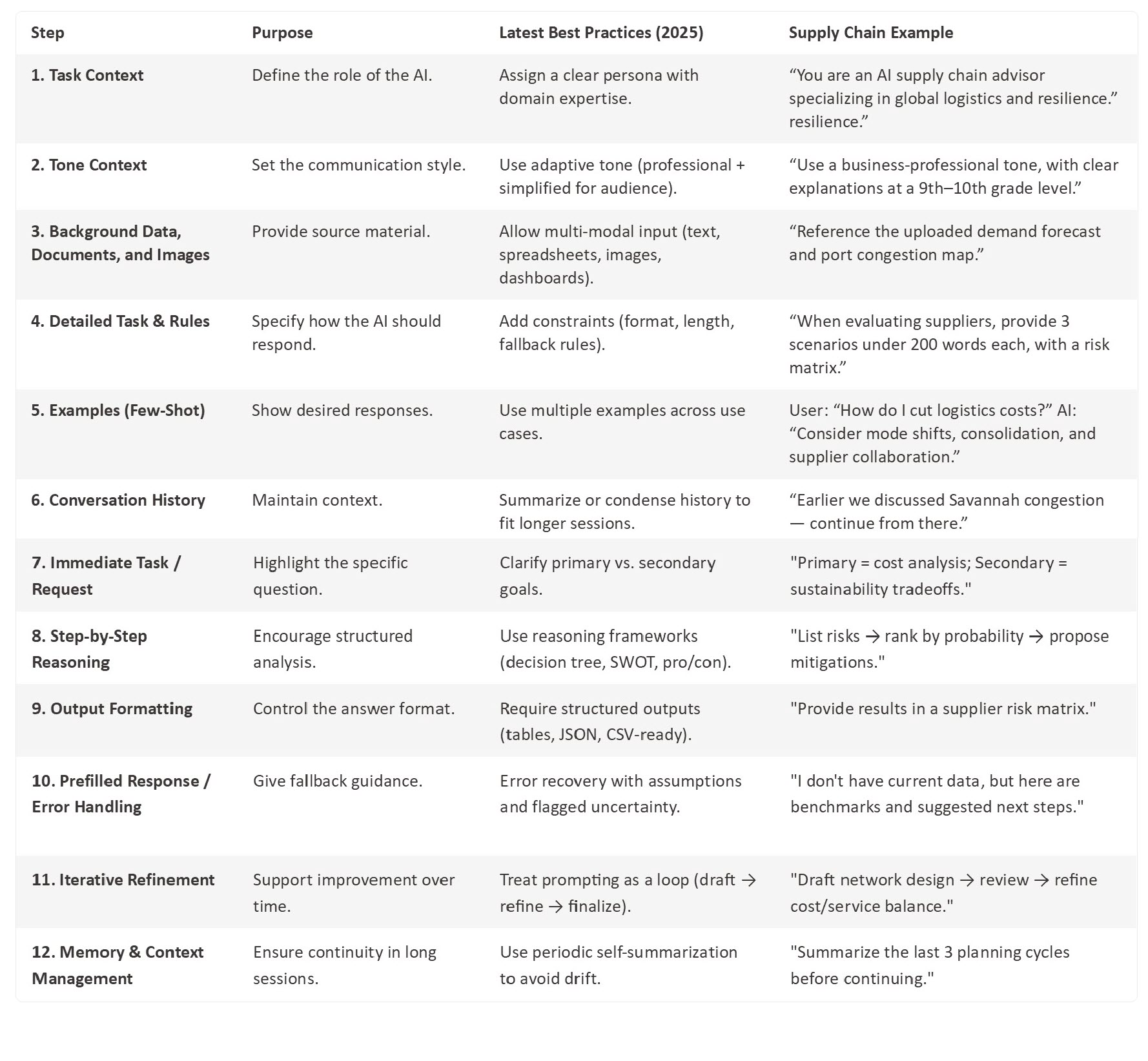

2. Prompt Maturity is the New Literacy

I’ve personally learned the most about prompting by asking ChatGPT to critique my style against a 12-step framework. The feedback gave me a process improvement plan I still use today. Prompt maturity isn’t abstract — it’s a measurable, improvable skill.

💡 Applied step: Rewrite one work prompt per week by climbing the ladder.

3. Unlocking Personal Productivity

One of the fastest returns from GenAI comes from personal productivity. In our short courses this year, I’ve seen learners gain comfort and lower stress as they practice more with the tools. Many reclaimed time by using GenAI for emails, presentations, meeting notes, and data prep.

While the list of GenAI time-saving strategies is broad, some uses are already mainstream and validated by thousands of professionals. The table below organizes these strategies into categories, provides guidance on how to accomplish them, and highlights common watch-outs to ensure they deliver value without risk.

💡 Try this week: Track one workflow where AI saved time and estimate the hours reclaimed.

4. Critical Thinking: Ironically More Important than Ever

We wrote about critical thinking and added it to our curriculum after studies raised concerns about overreliance on AI. The smarter the tools become, the more important it is to validate their outputs.

💡 Applied step: Take one AI output this week and run it through the checklist — you’ll see both strengths and blind spots.

5. Advocating for Strategy and Guardrails

We’ve seen firsthand how AI policies can evolve. One major retailer shifted in less than a year from a rigid “only data scientists experiment” model to encouraging all employees to try safe versions of multiple LLMs. This shift shows why professionals should advocate for strategy and guardrails that evolve with the technology.

💡 Ask your manager: Which of our daily tasks fall into green, yellow, and red today?

6. Agents: Early but Essential

Many industry partners are actively testing agents. Our software partners are hitting singles and doubles now, with bigger “home run” opportunities still developing. Agents aren’t fully reliable yet, but they are advancing quickly and will increasingly appear in ERP, TMS, and WMS platforms.

In practice, most organizations today sit between Level 1 (Exploratory) and Level 2 (Task-Specific Agents), with early pilots pushing into Level 3 (Augmented Workflows). Tech-forward enterprises — particularly in retail, e-commerce, and global manufacturing — are building domain-specific agents for forecasting, procurement support, and transportation planning, often embedded inside ERP or planning platforms. These companies are experimenting with multi-agent coordination but keep humans firmly in the loop. By contrast, mainstream companies are still largely in the exploratory stage: individuals using general copilots for drafting documents or ad hoc analysis, without enterprise integration, security controls, or governance. The gap is widening — forward-leaning firms are developing playbooks for orchestrated workflows, while many organizations are just beginning to set policies and figure out where AI fits safely into their operations.

Looking ahead, Level 4 (Collaborative Automation) is where the near-term breakthroughs will happen. In the next 3–5 years, we can expect multi-agent orchestration to become a practical tool for managing recurring disruptions — think transportation rerouting during weather events or automated supplier alerts when delivery milestones are missed. Early adoption will occur in large, tech-forward enterprises with strong governance and secure infrastructure. Level 5 (Autonomous Resilience) remains aspirational: while the vision of end-to-end supply chain automation is compelling, regulatory hurdles, trust, and explainability challenges mean human oversight will remain essential. The more realistic trajectory is that enterprises will selectively automate narrow disruption scenarios while maintaining tight human control, with broader autonomy coming only as governance, standards, and trust mechanisms mature.

💡 Applied step: Identify one repetitive process in your work that could be a candidate for an agent.

7. Human in the Loop: Non-Negotiable

Competition has improved model quality this year — but hallucinations and memory issues remain. That’s why “human in the loop” is not just a principle; it’s operational reality. AI is still an assistant, not a replacement.

💡 Applied step: Write down one checkpoint you always apply before sharing AI outputs.

Conclusion

These observations — from teaching courses, updating curriculum, and watching partners experiment — motivated this article. GenAI is evolving at extraordinary speed, and our profession must evolve with it. Build your plan, refine your prompts, reclaim time, apply critical thinking, advocate for strategy, explore agents, and always keep the human in the loop. Those who do will thrive in 2026 and beyond.

Sep. 23, 2025

Smart manufacturing, data-driven design, and artificial intelligence aren’t just buzzwords — they are fields that are creating high-paying, high-tech careers across the country. In rural communities across Georgia, these advanced manufacturing roles are growing, but the talent pipeline isn’t keeping pace.

“It’s not just about creating jobs, it’s about filling them,” says Tom Kurfess, Regents’ Professor in mechanical engineering and executive director of the Georgia Tech Manufacturing Institute (GTMI). “To do that, we need to show students how exciting and innovative manufacturing can be. Manufacturing has really changed over the past few years. Today, going from an idea to a physical part is much easier to do. It is fun and exciting to bring ideas to life and to actually hold the results in your hands.”

GTMI is working to reignite student interest in the art and science of making through its new K–12 initiative: the Advanced Manufacturing Pathways (AMP) Program. Modeled after Georgia Tech’s Rural CS Initiative, AMP empowers schools with faculty expertise, cutting-edge equipment, and a hands-on curriculum to give students early exposure to the tools, technologies, and creativity behind modern manufacturing while building a pipeline of future talent ready to thrive in high-tech careers.

Funded by the Southwest Georgia Regional Commission (SWGRC), AMP is kicking off in three school districts this fall — Decatur County, Thomas County, and the city of Thomasville — with plans to expand to additional schools in the spring of 2026. The program will start by engaging more than 200 students through hands-on learning, virtual instruction, and in-person lab experiences led by Georgia Tech researchers and faculty.

“Here in Southwest Georgia, we believe that opportunities like this are vital for integrated learning in schools and for growing our future workforce,” says Beka Shiver, economic development and transportation planner for SWGRC. “Workforce development and K-12 integration are at the heart of our Southwest Georgia Ecosystem Building Project, and we are so pleased to be able to provide funding for this program.”

The launch of the AMP Program is centered around Design, Build, Race, a course putting a modern spin on the classic pinewood derby. Students will use digital design, 3D printing, and machining to build and race custom cars, while also learning how to collect and analyze performance data to improve their designs and predict outcomes. The course blends engineering with data science, sparking curiosity and showing students how modern manufacturing is powered by both technical skills and smart data.

“This program delivers real-world industry experience to students while strengthening the talent pipeline that drives innovation, competitiveness, and resilience in advanced manufacturing”, says Steven Ferguson, interim director of operations at GTMI and one of the project’s leaders. “After more than 20 years of driving education and workforce development innovation, I’m more energized than ever to help launch the AMP program to open doors for students and advance U.S. manufacturing leadership.”

Building the Blueprint

Before it evolved into the AMP Program, Design, Build, Race was a course developed by GTMI research engineer Kyle Saleeby in 2023. Originating in GTMI’s Advanced Manufacturing Pilot Facility (AMPF), the course was designed to introduce Morehouse and Georgia Tech students to the possibilities of modern manufacturing through digital design, 3D printing, machining, and competitive creativity.

“Even after the first week, it was powerful to watch students discover how exciting it is to design and manufacture a competition-ready car in a matter of hours,” said Saleeby. “That’s when I knew we were onto something special.”

Saleeby teamed up with Ferguson to transform the course into a broader initiative. The duo engaged colleagues from STEM@GTRI and secured funding from SWGRC to modify the curriculum and scale the course for a high school audience.

“We are thrilled that we have been able to take the lessons learned during the development of the Rural Computer Science Initiative and expand opportunities for students in Southwest Georgia,” says Sean Mulvanity, a senior research associate in the Georgia Tech Research Institute. Mulvanity is one of the founders of the initiative and has been a key contributor to the AMP Program. “We hope this program can grow and expose students across the state to the field of advanced manufacturing.”

Though granted by the SWGRC, funds for the program were provided by Georgia Artificial Intelligence in Manufacturing, a statewide initiative founded by GTMI and Georgia Tech’s Enterprise Innovation Institute to advance AI-driven manufacturing.

To bring AMP into classrooms, Southern Regional Technical College helped set up labs and provide technical support, ensuring schools were ready to launch.

“At all levels, the community has rallied around this program,” says Saleeby. “Providing students with a unique experience learning advanced manufacturing technologies will open countless career opportunities. I cannot wait to see where they go.”

News Contact

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

Sep. 16, 2025

As the U.S. works to strengthen its industrial base and reshore critical manufacturing capabilities, workforce development has emerged as a central challenge — and opportunity.

The Georgia Tech Manufacturing Institute (GTMI) recently welcomed its first Hiring Our Heroes (HOH) Fellow to help address this growing need. Lukas Berg, a retiring U.S. Army officer, will be working with GTMI to support new education and training programs aimed at preparing Georgians for careers in advanced manufacturing.

“Lukas Berg brings a unique blend of operational experience, academic insight, and a deep commitment to service,” said Thomas Kurfess, executive director of GTMI. “His perspective will be invaluable as we work to build stronger connections between Georgia’s communities and the advanced manufacturing sector.”

Hiring Our Heroes is a nationwide initiative led by the U.S. Chamber of Commerce Foundation that helps veterans and military spouses transition into civilian careers through short-term fellowships. Since 2021, Georgia Tech has hosted more than two dozen HOH fellows, beginning with U.S. Army veteran Erik Andersen, who now serves as interim deputy director for the Research, Electronics, Optics, and Systems Directorate at the Georgia Tech Research Institute (GTRI), where he also helps lead the HOH program.

Berg is the first fellow to be placed outside of GTRI, a sign of the program’s growing reach across campus and its potential to support a broader range of workforce development efforts.

“It’s been exciting to see how the Hiring Our Heroes program has grown at Georgia Tech,” said Andersen. “Berg’s placement at GTMI reflects the Institute’s commitment to connecting military talent with real-world innovation and workforce development. Veterans bring a unique perspective and skill set to these challenges, and I’m proud to see the program expanding to new parts of campus.”

Berg’s military career includes aviation command roles, teaching positions at West Point and the Joint Special Operations University, and deployments across multiple regions. At GTMI, he will be contributing to a new initiative that partners with rural school districts to introduce students to hands-on learning in advanced manufacturing, an effort designed to spark interest in high-potential career paths and support long-term workforce readiness.

With personal ties to Georgia Tech and a strong sense of purpose, Berg sees this fellowship as a meaningful next step. We spoke with him to learn more about what brought him to GTMI and how he views the role of manufacturing and workforce development in shaping the country’s future.

What inspired you to pursue a fellowship at the Georgia Tech Manufacturing Institute after your military service?

Last year, I visited Georgia Tech with many of the junior officers and pilots assigned to my helicopter battalion in Savannah. Our agenda included stops at the Georgia Tech Manufacturing Institute and the Advanced Manufacturing Pilot Facility, both of which struck me as being absolutely vital to maintaining the technological edge required to fight and win on the modern battlefield. Pursuing a fellowship at GTMI felt like a natural extension of my military service, and I suspected that it would put me back at the intersection of thinkers and doers (where I have always felt most at home).

You mentioned your grandmother taught at Georgia Tech for over 30 years — how has her legacy influenced your academic and professional journey?

My grandmother, Maria Venable, was the first woman to serve as a full-time faculty member in Georgia Tech’s School of Modern Languages. She poured herself into both her family and her students, and I was lucky to count myself in both populations, as she agreed to tutor me for the AP German exam in high school (but only if I behaved as well as her students at Tech). Her example inspired me to pursue a teaching assignment at West Point halfway through my Army career, and I experienced the same joy in teaching that she did. It’s something that I will continue to do for the rest of my life, whether in a formal or informal capacity.

Can you share more about the specific initiatives you'll be working on at GTMI related to advanced manufacturing education?

Most immediately, I am joining a new GTMI initiative that partners with rural school districts to deliver several weeks’ worth of curriculum and hands-on practice in advanced manufacturing. We just kicked off a pilot program with Bainbridge High School in Decatur, and it’s exciting to see their students leveraging sophisticated systems to design and build Pinewood Derby cars that would make Cub Scouts across the country green with envy. Beyond this initiative, I hope to contribute to other efforts that get young people excited about careers in manufacturing and that assist adult learners in re-skilling and up-skilling for this high-potential industry.

What are you most looking forward to as you begin your fellowship at GTMI?

Georgia Tech feels like a physical and intellectual crossroads of modern civilization. I’m excited to not only contribute as a member of GTMI but also to learn about the countless other departments, institutes, and programs that are convening talent to solve the world’s thorniest problems.

What skills or insights are you hoping to gain during your time at GTMI that will support your next career chapter?

As an Army officer, I’ve been stationed across the country and deployed around the world, but Georgia has always been home. (Gladys Knight’s “Midnight Train to Georgia” has been a fixture on my playlist since I left for West Point at the age of 17.) Now back with my family, I look forward to using my time at GTMI to learn about my home state and identify ways that I can contribute to its near and long-term prosperity, whether through roles in academia, government, or private industry. I also look forward to expanding my network in all these communities, as no single one has a monopoly on problem-solving.

Why do you believe rebuilding America’s industrial base and manufacturing workforce is critical to national security today?

As a career aviator, much of my professional life was spent agonizing over the availability of parts to repair my helicopters. It seemed like there were never enough, and they always took too long to get to me. This experience, coupled with lessons learned from our support of Ukraine’s self-defense, contrasted starkly with my recent study of America’s 20th-century role as the “arsenal of democracy.” I’m convinced that we need to regain that reputation, and I would like to see Georgia at the forefront of associated design, manufacturing, and education initiatives.

How do you see veterans playing a unique role in strengthening the U.S. manufacturing workforce?

I think veterans are the most natural candidates in the world for roles in the manufacturing workforce. They possess the knowledge, skills, and abilities to be successful in most endeavors, but most are looking for ways to extend their service beyond their time in uniform. What better way than to contribute to a field that is so vital to our national security and prosperity?

What does “Progress and Service” mean to you, and what does it mean to you personally to be contributing to that mission?

I love Tech’s motto. I grew up in a family and community that reinforced at every turn the idea that our highest potential as human beings is realized when we serve others. This motivated my choice to serve in the military for the past 20 years, and it remains my North Star for this next chapter. I also love the idea of technological progress being the vehicle by which Georgia Tech collectively serves others, and I hope to accelerate this progress during my time at GTMI.

If you could give one piece of advice to other service members considering a fellowship like this, what would it be?

Inventory your passions and define your purpose. Then start reaching out to people in related fields. I have been amazed at how generous people have been with their time and how eager they have been to help me find my second calling and related opportunities.

News Contact

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

Sep. 12, 2025

Robotic systems are currently deployed in sectors ranging from industrial manufacturing to healthcare to agriculture, adding benefits in production times, patient outcomes, and yields. This trend towards greater automation and human robot collaborative work environments, while providing great opportunities, also highlights a critical gap in cybersecurity research. These systems rely on network communication to coordinate movement, meaning that security breaches could result in the robot acting in ways that may endanger people and property.

Current cybersecurity approaches have been shown to be insufficient in blocking sophisticated attacks aimed at networked robotic motion-control systems.

To address this gap, Jun Ueda, Professor and ASME Fellow in the George W. Woodruff School of Mechanical Engineering at Georgia Tech, has been awarded approximately $700,000 by the National Science Foundation to establish methods to enhance cybersecurity for networked motion-control system. The research will focus on the unique geometric vulnerabilities in networked robotic systems and stealthy false data injection attacks that exploit geometric coordinate transformations to maintain mathematical consistency in robotic dynamics while altering physical world behavior.

Using an interdisciplinary approach that will combine research methodology from system dynamics, control, communication, differential geometry and cybersecurity engineering, Ueda hopes to establish new mathematical tools for analyzing robotic security and develop safer networked robotic systems that successfully repel system intrusion, manipulation attacks, and attacks that mislead operators.

This article refers to NSF Program Foundational Research in Robotics (FRR) Award # 2112793

A Geometric Approach for Generalized Encrypted Control of Networked Dynamical Systems

News Contact

Sep. 09, 2025

Two Georgia Tech researchers in the College of Engineering have been named finalists for the 2025 Blavatnik National Awards for Young Scientists. Their discoveries, which could create cleaner industrial processes and safer, more reliable batteries, have important potential impacts for daily life.

The Blavatnik Awards are presented by the Blavatnik Family Foundation and are administered by the New York Academy of Sciences. They honor the most promising early-career researchers in the U.S., across life sciences, chemistry, and physical sciences, and engineering. The awards are among the most prestigious and competitive in science.

This dual recognition underscores Georgia Tech’s growing national leadership in high-impact, interdisciplinary research.

Ryan Lively, Thomas C. DeLoach Jr. Endowed Professor in the School of Chemical and Biomolecular Engineering, is recognized in the Chemical Sciences category for pioneering scalable technologies that will reduce industrial carbon emissions and energy use. He develops new materials that can capture carbon and separate chemicals, using much less energy than conventional methods. His innovations could make industry cleaner and play a key role in addressing climate change.

Matthew McDowell, Carter N. Paden Jr. Distinguished Chair in the George W. Woodruff School of Mechanical Engineering holds a joint appointment in the School of Materials Science and Engineering. Recognized in the Physical Sciences and Engineering category for groundbreaking battery research, he and his team develop new materials to make batteries last longer and store more energy. He has discovered ways to visualize how battery materials change during use — insights that help improve the performance and safety of future energy technologies.

This year’s 18 finalists were selected from 310 nominees. On Oct. 7, 2025, three laureates will be announced at a gala at New York City’s American Museum of Natural History. Each laureate will receive $250,000, the largest unrestricted scientific prize for early-career researchers in the U.S.

News Contact

Shelley Wunder-Smith shelley.wunder-smith@research.gatech.edu

Aug. 28, 2025

Srinivas Peeta, the Frederick R. Dickerson Chair in Transportation Systems at Georgia Tech’s School of Civil and Environmental Engineering, has been appointed Co-Editor-in-Chief of Transportation Research Part B: Methodological. This prestigious journal focuses on the mathematical and analytical foundations of transportation systems, addressing critical challenges in areas such as traffic flow, network design, control and scheduling, optimization, queuing theory, logistics, and behavioral modeling.

Transportation Research Part B complements other journals in the series—Part A (Policy and Practice), Part C (Emerging Technologies), and Part D (Transport and Environment)—forming a comprehensive suite of publications that collectively represent the forefront of transportation science. The journal serves a diverse and specialized audience, including operations researchers, logisticians, economists, econometricians, mathematical modelers, transportation engineers, geographers, and planners.

Professor Peeta brings decades of experience to this role. His research spans dynamic traffic assignment, congestion mitigation, and the development of resilient transportation networks. His association with Transportation Research Part B began in the early 1990s as a reviewer, and he has since published approximately 25 papers in the journal. Since 2019, he has served as an Associate Editor, playing a key role in managing the editorial process and upholding the journal’s high standards.

Please join us in congratulating Professor Peeta for this well-earned recognition. We are confident he will continue to guide Transportation Research Part B with excellence and vision, shaping the future of transportation research.

News Contact

info@scl.gatech.edu

Aug. 25, 2025

By Chris Gaffney, Managing Director, Georgia Tech Supply Chain and Logistics Institute | Supply Chain Advisor | Former Executive at Frito-Lay, AJC International, and Coca-Cola

Introduction

Artificial intelligence has entrenched itself in almost every aspect of the professional world. From copywriting tools to search engine optimization and image generation, professionals and laypeople alike use this new technology to streamline daily activities. But, before AI, there was high-level analytics and machine learning in supply chain. Analysts across the supply chain used machine learning to interpret high volumes of data and turn it into predictive algorithms for inventory planning, demand planning, and more. Now, AI is generating these analytics at a much faster, real-time pace.

This shift raises important questions. What does this mean for technology professionals in the supply chain world who once made a living doing these jobs? And what can we expect for aspiring supply chain pros or mid-career professionals who want to increase their value to the team in an age of accelerated technological advances?

The fact of the matter is that AI is now everybody’s job. Standing still will ensure that you get left behind by your peers or the talent pipeline from colleges and universities. The question then becomes, how can I upskill and use what I already know to add value to my role and ensure that my AI competencies allow me to compete in today’s supply chain workforce?

We’ll look at the ladder as a series of increasing levels of complexity and AI activity—what we’ll call ‘maturity levels’: descriptive, diagnostic, predictive, prescriptive, cognitive/autonomous, and integrated enterprise.

Some things to bear in mind as we progress through this topic:

- Everybody is somewhere on the ladder, so everyone has the opportunity to climb the ladder.

- Analytics are no longer just for specialists. AI allows analytics to be an access point to the ladder. You no longer have to rely on someone else higher up on the ladder, and it’s in your best interest to climb higher, regardless of your job description.

- There are lots of resources freely available to allow you to climb the ladder. But in most companies, you can find a mentor who is further along on a ladder, and perhaps they can help you up-skill your operational knowledge and help you advance your capabilities to ascend the ladder.

We’re here to discuss to what degree you should so you can optimize your career opportunities and not be left behind.

How Did We Get Here?

In the field of supply chain we’ve always been ahead of the curve when it comes to these types of innovations. Before AI, we were using machine learning and predictive analytics to enhance our understanding of real-time supply issues. We worked a lot on optimizations at Coke and started utilizing machine learning tactics almost 10 years ago. While I wasn’t the hands-on user of the technology, I took it upon myself to try and understand exactly what was happening and how it was working.

That was a large corporate machine–one of the biggest brands in the world–utilizing the latest in predictive analytics technology. And now we have a democratization of this technology being spread across industries. You no longer need to be part of such a high-powered team to make use of these tools.

We have now entered into an era where artificial intelligence has become omnipresent across almost every supply chain practice and industry, or any other career discipline. The key is understanding best practices is making use of AI in your field, and how you can add value and incorporate it into your everyday work-life.

Descriptive Level: From Rearview Mirror to Forward Thinking Decisions

“If you have some proficiency in Excel, then you’re on the ladder.” - Chris Gaffney

The lowest rung on the AI ladder is the descriptive level. Excel knowledge and experience resides here and can be the access point for most people. This level helps us describe what is happening with numbers and data. Reporting dashboards can be crafted here, and we can run trend analysis using basic inference to see what is happening and where to make adjustments, if necessary.

Excel tells us what did happen - not what could happen. These are important functions, to be sure. However, they only look behind us. They tell us what and why. Today’s supply chain landscape requires tools that allow us to make decisions based on what could happen in the future. We don’t have the power to make proactive decisions or to navigate uncertainty and factor in variables of change.

Our competitive edge is sharpened by having the capability to shape the future, not just explain the past. In order to do so, we need to move up into predictive and prescriptive AI territory.

Up until very recently, this descriptive capability was enough. Analysts, planners, and buyers were all able to produce data that helped others to understand what was happening. The data then required synthesis and analysis. The whys and so whats were human functions performed by different team members and used to measure the efficacy of various inputs and outputs throughout the supply chain. As one moves up the chain of command, so to speak, the ability to interpret the data and findings becomes even more important. However, the numbers crunching and analytics were more siloed.

And now, everyone has access to AI’s ability to synthesize and analyze raw data. But very few “off-the-shelf tools” can answer the why, let alone the ‘what should we do about it’ questions. Planners and managers need to upskill and ensure that they are up to speed on the capabilities and deficiencies of these platforms and insert themselves and their skillsets to close those gaps.

Roles at this level:

- Transportation analysts

- Warehouse supervisors reviewing daily throughput metrics

- Demand planners tracking forecast accuracy from the last quarter

Working in hindsight by monitoring and measuring data is important, albeit limiting. This looking backward in the world of supply chain decision making at a time when forward thinking is essential for future proofing your supply chain organization. Staying here too long limits your ability to prevent problems before they escalate.

What to do next?

- Learn Power BI or Tableau for interactive dashboards

- Get comfortable using large data sets from your ERP or WMS

- Start asking, “why” and “so what”

Diagnostic Level - Information into Insight

“This is where you start to become more valuable because now you can help the team avoid repeat issues.”

So you’ve now measured what happened. The next logical question is why? Here’s where many companies fall short by relying on only internal historical data. The real learning happens when you bring in external variables like weather, economy, labor, or competitive actions. Diagnostics help uncover root causes and patterns across time and systems. What does this mean for you and the AI ladder?

This could mean combining two different datasets using SQL to pull deeper reports or identifying correlations between variables. You need to be able to get inside of your supply chain to see what’s really going on, much like a physician will draw blood or perform various scans to get a more vivid and comprehensive picture of what’s happening.

Examples from the field:

- A demand planner diagnosing why forecasts were consistently off by adding external factors outside your control.

- A transportation analyst finding route disruptions correlated with labor strikes and weather trends - kinda like WAZE.

What you can do

- Add layers of internal and external factors

- Use Power BI or Excel to show the impacts of external events

- Start to track leading indicators, not just lagging ones.

Predictive - Seeing What’s Coming

“Most of the tools we have heavily leverage your own history. But your ability to sell a product next year is different because you don’t control everything.”

Predictive analytics enables supply chain professionals to see trends, forecast disruptions and plan proactively.

As we mentioned earlier, most forecasting tools rely too much on internal history. Predictive power comes from adding things like economic trends, labor availability, weather, etc., to your forecasting models.

My first exposure to the broader umbrella of machine learning, falling under AI, was while working at Coke. Every night, our machines processed enormous volumes of data to track how much of each type—across countless product combinations—was being used. This data was being used to predict when the fountain machines would fail so that we could prepare a replacement without losing time or operational capacity. Basically, this meant we could allocate maintenance resources proactively instead of reactively.

This machine learning doesn’t have to be intimidating. In fact, machine learning was the #1 skill in supply chain job postings in 2024. Python and machine learning are much more accessible tools than they once were, and many professionals are teaching themselves the basics using online resources that are much more prevalent than they once were. Again, the democratization of AI tools means everyone can level up a lot faster.

Roles Seeing This Shift

- Demand planners and sourcing managers are combining historical sales information with things like inflation, trade wars, and taste evolutions.

- Transportation teams are integrating weather trends and traffic data to reroute loads

What Can You Do:

- Learn the basics of Python’s forecasting libraries

- Pull in a single external variable, like weather or labor availability, into your demand forecast.

- Track model accuracy over time to see where it succeeds and, most importantly, fails.

Prescriptive: Deciding What to Do About It

"We don’t want analytics experts. We want people who are applied analytics or applied AI experts.”

It’s not just identifying the risk. The key is choosing a more effective path forward. And this requires modeling scenarios in a way that lets you take action rather than just be an observer.

A lot of companies stop at prediction. The ones that get ahead of the pack are those that are able to simulate outcomes and use this logic in daily decisions. Just remember that context is everything. Those with very impressive technical skills can sometimes miss the mark because they didn’t understand the business. There are also supply chain planners with moderate technical skills who can make major contributions because they knew what mattered and where to apply it.

The supply chain AI ladder is crucial, but only as effective as the depth of the supply chain knowledge base.

Cognitive and Integrated is When AI Starts to Work With You

This is the very top of the ladder or the tip of the AI ladder iceberg, if you will. This is the realm of AI agents that are learning and acting in an intelligent and sometimes autonomous manner. The cognitive tier blends into the integrated enterprise, where systems and data are connected. Warehouses talk to the forecast, which communicates with sourcing, which can adjust production. This is kind of futuristic, but based on how AI has evolved, it will likely be ubiquitous within a couple of years.

How to Apply Cognitive and Integrated AI:

- Learn how to build a basic GenAI or logic-based agent using online tutorials or sandbox tools

- Make sure the AI Agent’s work is sound before turning it loose on our business. The human element is still crucial in these cases.

Role of Leadership in Deploying the Supply Chain AI Ladder

“This can’t be a black box to you.”

Leaders need to know just enough about AI to advocate for it. If you’ve hired the right people, then you trust them to do the job that you hired them to do. If they’re telling you that AI tools will help them do their jobs better, then listen to them. Find out what your team needs and get them to explain to you how AI can unlock more benefits for your business.

Encourage them to pursue professional development courses and to experiment in a safe environment until they feel confident integrating the tools into regular operation.

Conclusion: Don’t Stand Still and Be Left Behind

The supply chain AI ladder is real, and it’s climbable. You are not too late to get on board and begin using AI to increase your personal value at your company. It doesn’t matter how old you are - whether you’re an entry-level professional with an MBA, a mid-career professional, or a seasoned C-suite executive. There is a place on the ladder for you.

The most valuable assets that employees can bring to bear right now in this tech immersion context. Those who have been in the workforce for a few years are able to mix their experiential knowledge with the tools and assets available through AI to translate technology into real-world wins for your supply chain teams. Your value increases significantly if you pair your knowledge with proactive learning tools.

Take the time to self-assess and figure out where you are on the ladder.

Don’t try to jump too high up on the level. Take it one rung at a time. Then reassess.

Commit to the 70/20/10 rule. 70% on-the-job learning, 20% learning from peers and mentors, and 10% formal training.

Apply what you’ve learned and stay curious. Just don’t get complacent. This is not the time to rest on your laurels because someone who is hungry for knowledge will be on your heels.

This content was developed in collaboration with SCM Talent Group, a supply chain recruiting and executive search firm.

Aug. 04, 2025

By Chris Gaffney, Managing Director, Georgia Tech Supply Chain and Logistics Institute | Supply Chain Advisor | Former Executive at Frito-Lay, AJC International, and Coca-Cola

A Personal Wake-Up Call

I’ve always considered myself a reasonably strong critical thinker—someone who asks good questions, challenges assumptions, and doesn’t adopt a viewpoint just because it’s popular. But a recent experience humbled me. I took an open-source critical thinking test and didn’t do nearly as well as I expected.

This led me down a deeper path of inquiry. I was already concerned about how two decades of social media have shaped the way we consume and respond to information—short, sensational content delivered by algorithm. And now, with the rapid rise of generative AI, I worry we may be trading our thinking for speed and scale.

I use AI tools daily, and I advocate for their use—especially in supply chain applications. But I’ve also come to believe this: if we’re not careful, we risk outsourcing the very thinking that makes us human and effective decision-makers.

Why Critical Thinking Matters More Than Ever—Especially in Supply Chain

Critical thinking isn’t just a defense mechanism—it’s a differentiator. In a world where AI can generate answers instantly, the professionals who ask the right questions will stand out.

Supply chain professionals operate in environments where second and third-order consequences matter. We are called on to make decisions under uncertainty, weigh risks, balance competing priorities, and understand interdependencies.

Judgment—tempered by experience, structured analysis, and humility—is the edge. Tools can help you scale, but they cannot replace the human responsibility to challenge, reflect, and adjust.

What Is Critical Thinking?

Critical thinking is the ability to think clearly and rationally about what to do or believe. It involves:

- Questioning assumptions

- Evaluating evidence

- Recognizing biases (ours and others’)

- Drawing reasoned conclusions

- Reflecting on one’s own thought process

Said simply, it’s self-awareness of your thinking style—how you form your views, test them, and revise them when new evidence emerges.

It requires effort. It requires slowing down. It requires, at times, being wrong.

Facione, in his Delphi Report, defines it as "purposeful, self-regulatory judgment."

Kahneman reminds us that our brains are wired for shortcuts—“System 1” thinking is fast and efficient but often error-prone. True critical thinking requires “System 2” effort: slow, reflective, and disciplined.

Are We Losing It?

There’s growing evidence we are.

Social media echo chambers reduce exposure to opposing views. Short-form content conditions us to expect fast answers. And according to the MIT Media Lab (Kosmyna et al., 2024), students using ChatGPT retained less, showed reduced cognitive effort, and had lower originality.

“When ChatGPT was used, cognitive effort declined.”

And yet—this is not a moment for despair. It’s a call to discipline. Because critical thinking, practiced intentionally, can become a personal and professional superpower.

Applying Critical Thinking in Supply Chain Decisions

Supply chain professionals face complexity daily—inventory tradeoffs, supplier uncertainty, resource constraints, policy risk. Many of these decisions can’t be answered by tools alone—they require judgment. Critical thinking lives in that judgment.

Whether you're building a forecast, evaluating a supplier, responding to a disruption, or modeling risk exposure, structured thinking provides a path. The steps are familiar:

- Define the problem clearly

- Clarify what information is available—and what’s missing

- Analyze root causes or future implications

- Generate multiple options

- Establish decision criteria

- Choose a path—and test it before launch

- Monitor and adjust as feedback arrives

This process resembles A3 thinking or supply chain analytics. But what makes it powerful is doing it intentionally—even under pressure.

The best professionals I’ve worked with practice it on small decisions as well as large ones. They don’t confuse speed with clarity.

Practicing Critical Thinking When Using Generative AI

AI tools are powerful—but without deliberate use, they can dull our thinking. Here's how to make AI work with your brain—not instead of it:

- Document your assumptions before prompting

- Journal your intent: What are you trying to decide or explore?

- Ask AI to provide counterarguments or alternative views as well as sources for you to research and draw your own conclusions

- Look for what’s missing or oversimplified

- Summarize AI output in your own words

- Track and reflect on how AI influenced your decisions

Treat AI like a research assistant—not a strategist. Use it to extend your reach, not replace your reasoning.

Final Thought and Your Next Steps

Critical thinking is no longer optional. Not in business. Not in education. Not in leadership.

It is a skill. A discipline. And a mindset that pays dividends over a lifetime.

If you’ve read this far, take this challenge seriously:

- Write out how you form your opinions—on paper.

- Practice structured thinking on small problems weekly.

- Use AI with intention—never outsource your judgment.

- Teach someone else how you reached a conclusion.

- Be humble. Ask yourself: what if I’m wrong?

- Keep a thinking journal for 30 days.

The goal isn’t to be right all the time. It’s to be reflective, rigorous, open to challenge, and consistent over time. That’s what the world needs more of. That’s the edge AI can’t replicate.

So think before you automate.

And never stop questioning.

Jul. 14, 2025

By Chris Gaffney, Managing Director, Georgia Tech Supply Chain and Logistics Institute | Supply Chain Advisor | Former Executive at Frito-Lay, AJC International, and Coca-Cola

Every few weeks these days, a new AI breakthrough makes headlines. Models get sharper and more capable. Language tools get more fluent. Claims of agent breakthroughs and embedded autonomy in tools are everywhere.

And each time, the question resurfaces: What’s left for people to do as this wave progresses?

It’s a fair question. But from what I’ve seen throughout my career—from managing logistics in a Frito-Lay regional DC to transportation and distribution operations at AJC International and Coca-Cola, and now through executive education, consulting, and applied research at Georgia Tech—I believe we’re asking the wrong question.

Instead of asking what AI can do, we should be asking: Where is the human edge—and how do we keep it sharp?

1. Collaboration Across Boundaries Still Wins the Day

Whether in manufacturing, logistics, commercial and customer teams, or strategy, success still hinges on people working together—often across silos, systems, or supply chains. At Coca-Cola, some of the most impactful progress we made didn’t come from technology upgrades. It came from aligning teams that didn’t naturally collaborate—finance with planning, supply chain with sales, bottlers with company.

From what I see in my advisory work and interviews with supply chain leaders, that hasn’t changed. AI can improve visibility. It can suggest decisions. But it doesn’t build consensus, resolve conflicts, or create shared understanding. That’s human work—and it often makes the difference between potential and progress.

2. When the Plan Breaks, People Step Up

During my time in global logistics at AJC International, unexpected events were the norm: shipping delays, capacity shortages, regulatory changes. AI may help flag risks, but when the plan breaks, it’s still people who step in, prioritize under pressure, and find creative solutions.

This same theme came up in a recent SCM Talent podcast conversation. When I asked a senior supply chain leader what traits define her most effective team members, she didn’t hesitate:

“A drive for results. Problem solving. The ability to work in teams. And the ability to influence others.”

Those aren’t going out of style. They’re still what carries teams forward when the data model breaks or the shipment gets stuck.

The professionals I see excelling—especially in moments of disruption—aren’t just technical experts. They’re problem solvers who own the outcome and stay focused when others get stuck.

Drive, persistence, and adaptability aren’t things you automate. They’re human qualities that remain essential.

3. Hands-On Context Isn’t a Field Trip—It’s a Foundation

At Frito-Lay, I worked in a regional distribution center and breakbulk operation managing warehouse activities and dispatching drivers. Later, I spent a full year as an operations manager at one of our plants, where I led drivers and worked with plant warehouse teams and schedulers to ensure load readiness and on-time dispatch to local DCs.

Those weren’t just jobs—they were formative experiences. They taught me how decisions affect execution in the real world, and how the rhythm of operations shapes everything else in the supply chain.

That’s why I firmly believe professionals—especially early in their careers—should spend 3 to 5 years in front-line roles. No AI tool can replicate the kind of intuition you build by seeing how things work, where they break, and how people respond in real time. That foundation lasts an entire career.

4. Communication and Leadership Will Always Matter

In every role I’ve had—from the plant floor to corporate teams to Georgia Tech—I’ve seen that clear communication and authentic leadership are force multipliers. They carry more weight now, not less.

AI might help with drafting, summarizing, or visualizing, but it doesn’t earn trust. It doesn’t mentor a new team member or guide a group through a difficult change. That takes listening, emotional intelligence, and personal credibility.

Those leading change in today’s organizations—whether rolling out a new system or rebuilding after disruption—are the ones who can communicate with clarity and lead with steadiness. That’s not something AI can learn.

5. The Edge Is Where Humans Live

There’s a space at the boundary of every operation—the “edge”—where plans meet real-world variability. And that’s where humans remain essential.

Whether it’s spotting an issue before it escalates, reading between the lines of a conversation, or connecting seemingly unrelated problems across functions, that kind of judgment is rooted in experience. It can’t be downloaded or inferred from data alone.

In my work at Georgia Tech, across executive education, consulting, and applied research, I regularly see the difference it makes when decision-makers bring not just technical knowledge, but lived context from the field. That human edge is where resilience is built—and where strategy becomes reality.

6. Humans and AI: Better Together

To be clear: this isn’t about rejecting AI. The smartest teams I work with aren’t afraid of it—they’re learning how to use it. AI tools can improve productivity, identify trends, and help people make better decisions. But they need to be paired with human insight.

AI suggests. People choose. AI speeds up planning. People keep it grounded. The professionals who combine digital fluency with interpersonal skill, operational awareness, and strategic judgment? Those are the ones who will lead in the next era.

So What Should You Do?

If you want to build a career that endures—and evolves—with AI, here are seven things I recommend:

- Invest in the front line. Not just a tour. Spend 3–5 years in a real operations or customer-facing role. It will shape how you lead for decades.

- Build bridges. Learn how sales thinks. Understand finance’s constraints. Connect systems, teams, and people.

- Volunteer when the extra project comes up. These stretch roles are often tied to strategic initiatives and senior leadership. Saying yes can accelerate learning and visibility—especially when others hesitate.

- Take roles at the intersections—not the cul-de-sacs. Look for positions that connect functions, partners, or ecosystems. Exposure to diverse perspectives sharpens insight and multiplies your value.

- Sharpen your communication. Speak with intent. Write with clarity. Listen deeply. These skills amplify everything else.

- Evolve with AI—or fall behind. You don’t need to code, but you do need to understand how AI is changing your domain. Through continuing education, hands-on learning, or professional development, stay curious and current.

- Never stop learning. At Georgia Tech, I see firsthand how ongoing learning—through executive education, research engagement, or new assignments—helps professionals lead through change. Keep asking: what haven’t I seen yet? Who could I learn from?

Final Thoughts

The future of work isn’t about humans vs. machines. It’s about people who can lead, decide, and connect—with AI as their force multiplier.

We may automate tasks. But judgment, trust, and empathy? Those are human domains. And in times of uncertainty, it’s the people who can navigate complexity, rally teams, and adapt with integrity who make the difference.

So yes, learn the tools. Embrace the change. But never underestimate the power of experience, context, and connection.

That’s your edge. And that’s not going anywhere.

Jul. 10, 2025

Researchers at Georgia Tech have developed a new artificial intelligence tool that dramatically improves how companies plan their supply chains, cutting down the time and cost it takes to generate complex production and inventory schedules.

The tool, known as PROPEL, combines machine learning with optimization techniques to help manufacturers make better decisions in less time. It was created by researchers at the NSF AI Institute for Advances in Optimization, or AI4OPT, based at Georgia Tech under Tech AI (the AI Hub at Georgia Tech).

The technology is already being tested on real-world supply chain data provided by Kinaxis, a Canada-based company that supplies planning software to global manufacturers in industries ranging from automotive to consumer goods.

Vahid Eghbal Akhlaghi, senior research scientist at Kinaxis and former postdoctoral fellow at AI4OPT and the H. Milton Stewart School of Industrial and Systems Engineering (ISyE) at Georgia Tech, said, “Our industry partner has been instrumental in shaping PROPEL’s capabilities. By validating the approach with real operational data, we ensured it addresses true bottlenecks in supply chain planning.”

"PROPEL represents a leap forward in how we tackle massive, complex planning problems," said Pascal Van Hentenryck, lead researcher, the director of Tech AI and the NSF AI4OPT Institute, and the A. Russell Chandler III Chair and Professor at Georgia Tech with appointments in the colleges of engineering and computing. "By combining supervised and reinforcement learning, we can make near-optimal industrial-scale decisions, an order of magnitude faster."

Traditional supply chain planning problems are typically solved using mathematical models that require immense computing power—often too much to meet real-time business needs. PROPEL, short for Predict-Relax-Optimize using LEarning, reduces this burden by teaching the AI model to first eliminate irrelevant decisions and then fine-tune the solution to meet quality standards.

Reza Zandehshahvar, one of the paper’s co-authors and postdoctoral fellow with the NSF AI4OPT and the H. Milton Stewart School of Industrial and Systems Engineering (ISyE) at Georgia Tech, said the breakthrough lies not just in the AI algorithms but in how they're trained and deployed at scale.

“Many AI models struggle when applied to problems with millions of variables. PROPEL was built from the ground up to handle industrial complexity, not just academic examples,” Zandehshahvar said. “We’re seeing real improvements in both solution speed and quality.”

In trials using Kinaxis’ historical industrial data, PROPEL achieved an 88% reduction in the time needed to find a high-quality plan and improved solution accuracy by more than 60% compared to conventional methods.

While many AI methods in supply chain rely on simulated data or simplified models, PROPEL’s performance has been validated using real-world scenarios, ensuring its reliability in high-stakes operational settings.

The Georgia Tech team says PROPEL could benefit industries that manage large, multi-tiered production networks, including pharmaceuticals, electronics, and heavy manufacturing. The researchers are now exploring partnerships with additional companies to deploy PROPEL in live environments.

Access the abstract on arXiv.

News Contact

Breon Martin

AI Marketing Communications Manager

Pagination

- Previous page

- 2 Page 2

- Next page